PE-HD - High-density polyethylene Extruder. Please consult your material and.

Barrel Temperature Profiles In C Download Table

The molten plastic is passed through a die to give.

. Barrier Screw 25 - 30 LD Compression Ratio. Points range from 250F340F 121C171C while melt temperatures suitable for processing will be generally about 20C higher. PP - Polypropylene Extruder.

Orifice dies multistage dies and tapered profile dies. No 3 hours at 105-110C 221-230F for regrind Calibration. The term heat-stabilized refers to these service temps.

It implies inclusion of antioxidant additives but not necessarily the same. At present three types of profile dies are used. 150C at infeed zone to 205C at the die gives highest output.

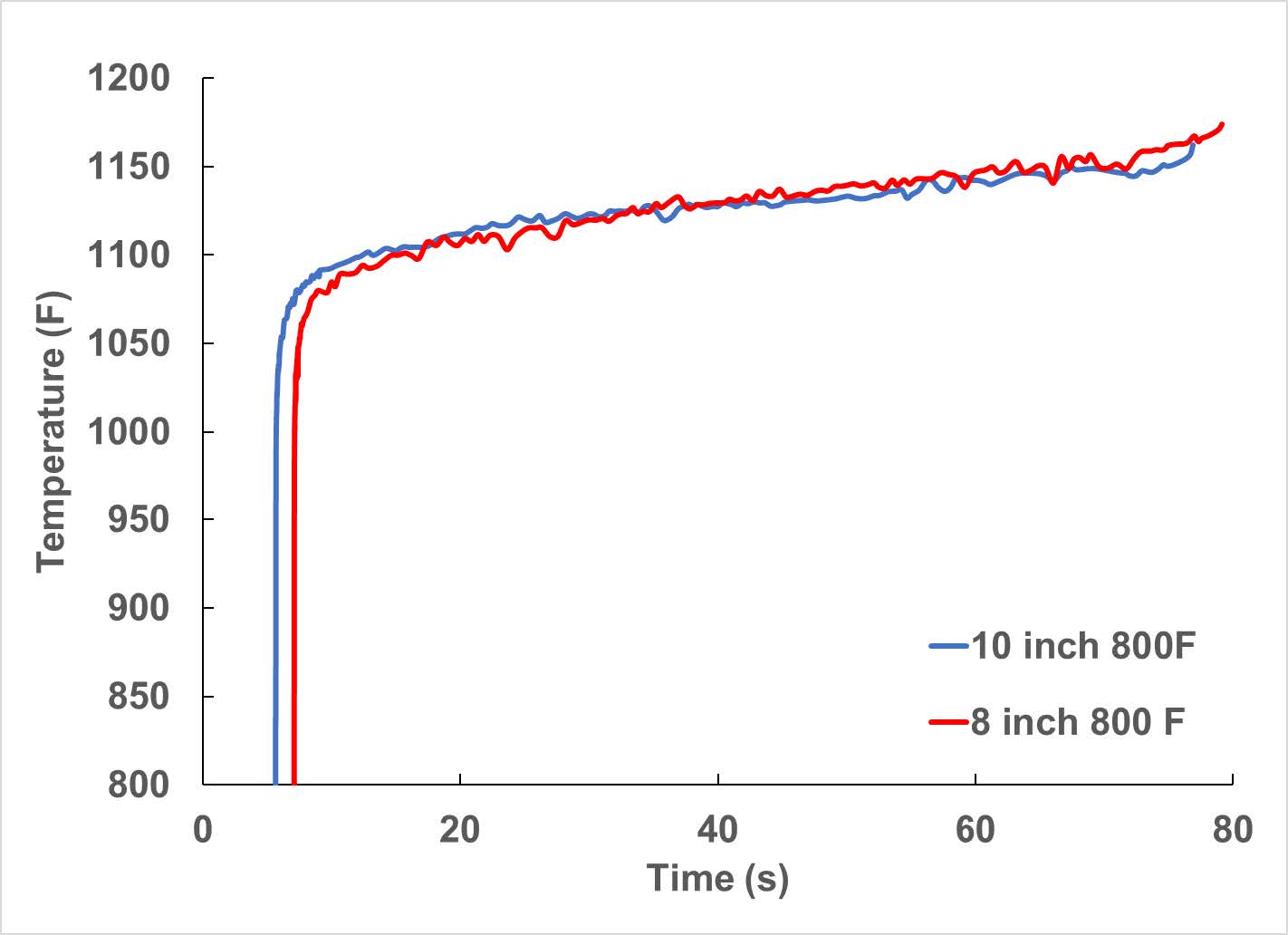

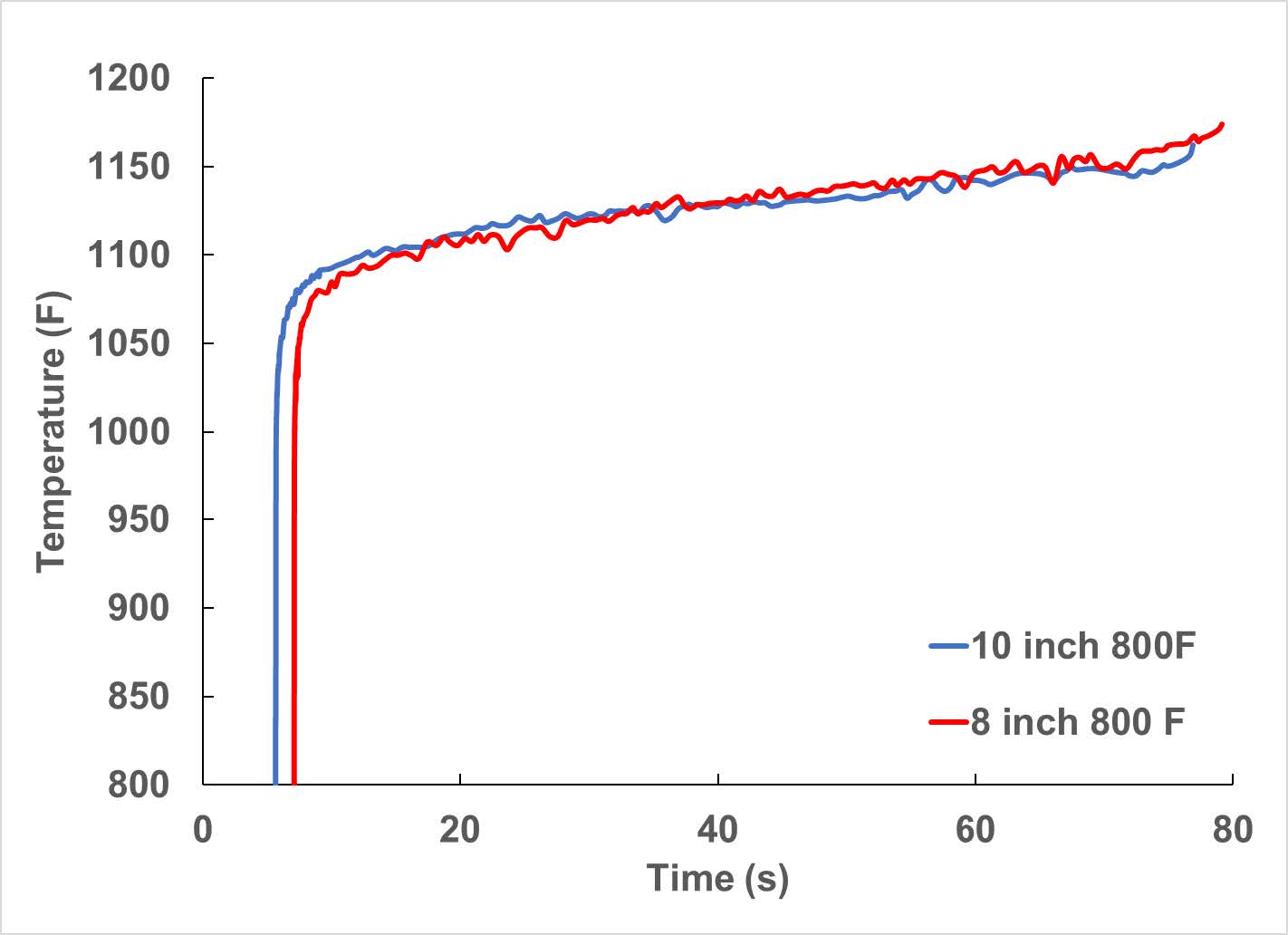

If the rate seems too low try raising the set points on zones 2 and 3 above the set points of the other zones to form a hump in the profile. This is not a radical concept. And since cooling often controls the output of many extrusion operations its important to process at the lowest usable temperature.

Harder grades will require higher temperatures to achieve a homogenous melt. 180-205C 356-401F Melt Temperature. Dont confuse process temperatures with service temperatures especially with materials like nylons which may be at 500 F for a minute or less in processing but the product may have to resist 350 F for an hour or 200 F for months.

The plastic extrusion process is a straightforward procedure that involves melting down resin beads raw thermostat material filtering it and then designing it into a given shape. Durch Extrusion können Profile mit komplexen Querschnitten in beliebiger Länge erstellt werden. They will also have a narrower processing temperature range in which the melt viscosity is suitable for forming extrudate profiles.

Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections. A Du Pont nylon extrusion study noted that exit-melt-pressure fluctuations were seven times more extreme after the temperature of the two rear zones was dropped 50 deg F. The rotating screw helps in pushing down a heated barrel to a given temperature.

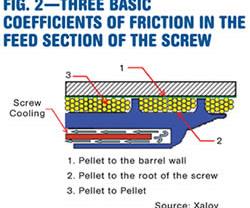

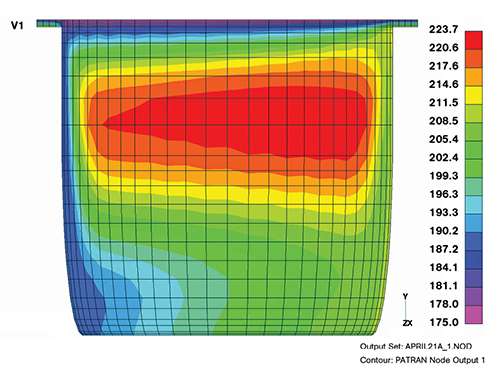

Single Screw Extruder with vacuum grooved feeding section Screw Design. Specifically we will look at pressures temperatures heating and cooling inside the extruder barrel. The optimal mode of L-profile extrusion from the modes under consideration is the heating of the billet 440 Cextrusion speed 05 mmin.

Temperature profiles vary greatly and include. All thermal performance data for one inch of extrusion All data is for Tambient 25C and P 10W MPN L mm W mm H of mmFins R 200 lfm oCW R 400 lfm oCW R 600 lfm CW R 800 lfm oCW R natural convection oCW R 200 lfm oCW Ducted ATS-EXL71-300-R0300 37 8 15 95 52 41 35 364 4 ATS-EXL71-1220-R01220. Barrier Screw 25-30 LD Compression Ratio.

Der Querschnitt des so entstandenen Profils mit dem Querschnitt der Öffnung des Werkzeugs in theoretisch beliebiger Länge. A Mobay processing handbook indicates that a 10-deg-F change in a 390F rear barrel zone can affect screw power by as much as 20 percent in extrusion of Texin 355D polyurethane. Proper temperature and heating control of the plastic inside of the extrusion barrel is very important to achieving high quality output whether you are a profile extruder wire coating sheet extruder or any other of the downstream processes.

The approach of using the narrowest possible flights has been common for years in foam cooling screws and other melt. 150 205C should not exceed 205C. This will often improve feeding and therefore the rate.

200-250C 392-482F Melt Temperature. Single Screw with vacuum grooved feeding section Screw Design. Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section.

Guidance on settings for injection moulding our TPE compounds. When optimum temperatures are reached it is known as the temperature profile. Basically the orifice die consists of a die base and a die plate in which the profile is formed.

Profile extrusion refers to the extrusion of polymer melts through dies of cross sections that are neither round annular or rectangular with an aspect ratio WH greater than 100. Die Extrusion von keramischen. If the temperatures on the first few zones are set too low you will sometimes see small gels or unmelted particles in the extrudate.

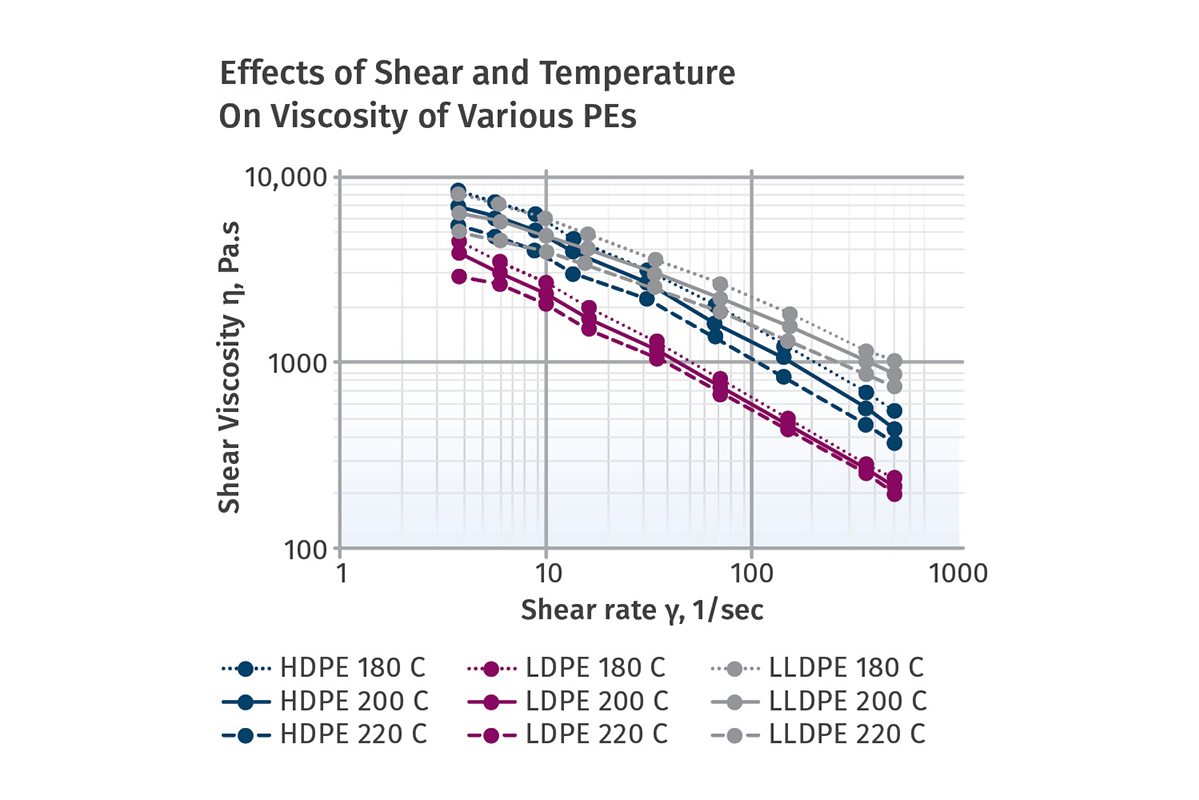

And to work materials that are brittle because the material encounters only compressive and shear stresses. Another consideration is the relatively low critical shear rate of these resins. This is meant as a general guide.

These two polymers have the highest extrusion temperature of all fluoropolymers with PFA processing temperature being the highest. The die temperature will also influence output and will have an effect on the dimensions of the extrudate. Most commercial grades of PFA have melting points in the range of 300310C and have high melt viscosity low MFR requiring the highest extrusion temperatures.

Understanding Plastic Extrusion. The optimal heating temperature of the billet before extrusion of rod is 440 C however at the temperature of 410 C a change in the profile speed from 05 to 11 mmin does not affect the yield strength. The effects of repetitive extrusion cycles at different die temperatures in a single screw extruder were investigated by thermal analysis degree of crystallinity χc heat of fusion ΔHm.

A cold die will restrict flow where as a too-hot die will affect dimensions. Use the power law coefficient as a guide to the effectiveness of this approach. Compression ratio should be low the melt sections should be fairly deeply threaded and the LD ratio should be 201.

Extrusion Extrusion Continuous Process In Principle The Plastic

Optimize Barrel Temperatures For Barrier Screws Plastics Technology

Extruder Barrel Temperature Settings Download Table

Schematic Illustration Of The Extrusion Line And The Temperature Of The Download Scientific Diagram

Article Extrusion Productivity Part I Billet Geometry Light Metal Age Magazine

Why Barrel Temperatures Have A Small Effect On Melt Temperature Plastics Technology

What Is Extrusion Plastic Extrusion Process Elastron Tpe

The Role Of Screw Design In Efficient Extrusion Of Medical Devices Plastics Technology

Example Of A Temperature Profile Of Plastic Extrusion Download Scientific Diagram

Extruder Barrel Temperature Settings Temperature Settings Set Download Table

Barrel Temperature Profiles In C Download Scientific Diagram

Understanding Viscosity In Extrusion Plastics Technology

Extrusion Ratio An Overview Sciencedirect Topics

Extruder Barrel Temperature Settings Temperature Settings Set Download Table